Frequently Asked Questions

1. What makes of CNC/PLC controllers are supported?

We have experience in supporting FANUC, Siemens, Mazak, Haas, Mitsubishi, and many more controllers. One Yantra Connect device can connect to multiple CNC machines with Ethernet. For Legacy machines with Serial Line (RS-232) Port, an extra adapter is required per machine. For machines with neither Ethernet or Serial we can tap from relays/Current Transformers and still get data from the machine, we leave no machine behind on your shop floor. Please reach out to us, so that we can propose the best solution

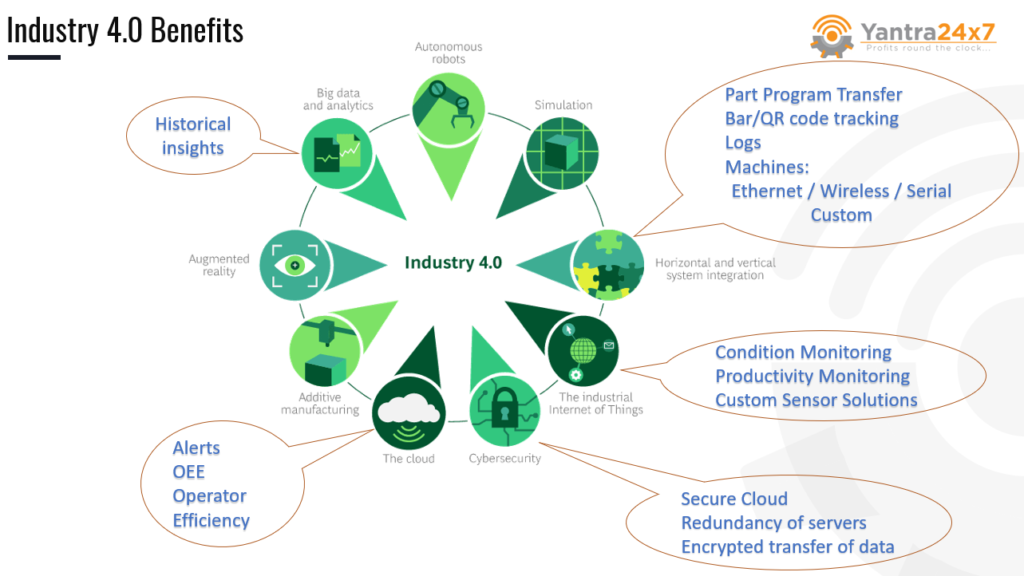

2. How is Industry 4.0 and Yantra connected?

Below figure shows the I4.0 system constituents, Yantra is progressing with different aspects as applicable to the machine shop

3. What are the Benefits in machine monitoring

● Efficiency increase in all steps of the manufacturing process

● Reduced waste

● Improved transparent communication throughout the organization

● Data collection and analysis that is provided in real-time, with alerts/notifications for data that fall out of established performance standards.

● Insights to make continuous improvement

4. How Can I Manage and Track My Shop Floor Activities In This Covid-19 Situation

● Yantra24x7 Vault eliminates Operator or Setter having to touch Card/USB Drive for Part Program Transfer.

● Yantra24x7 Connect makes paperless operation of shop floor possible, minimizing contacts between different persona by digitizing many operations

5. Can I install the Yantra solution myself?

Yes, With our Easy IP Config tool customers can self install following the simple instructions. Should you run into problems our Engineers will guide you on Phone, remotely connect and get your machine connected.

6. What do operators and the people on the floor think of machine monitoring?

(Is this more of “big brother” watching?)

Most of the employees on the shop floor know that they are being measured. Many of the employees feel that the current metrics are not the true measurement of their efforts and contribution in a transparent way.

With Yantra24x7, operators are empowered and engaged when they are able to view their performance metrics in a real-time feed.

7. How OEE machine monitoring can provide cost savings

OEE Machine monitoring provides real-time data that lets managers react while there’s time to make a difference. (Weekly or even just daily reporting only provides a historical snapshot, by which time it’s too late.) This ability to react quickly leads to significant cost savings.

8. Does Support for Multiple Shop Floor and Different Locations possible?

Yes, We Are Providing our Solution for Different or Various Locations of Shop Floor Anywhere, Any Place.

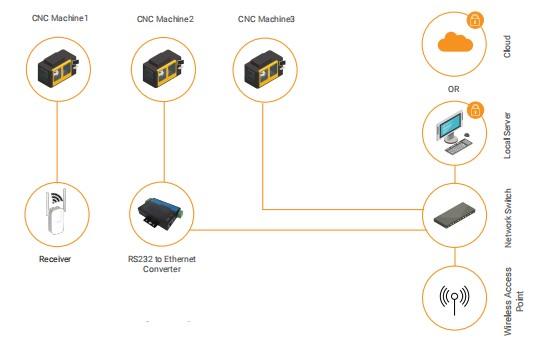

9. What wiring is needed to go live?

Below figure shows the different connection options supported by us

10. Is TV Andon board and Tablet essential for the solution to work?

No, We suggest you start with the Yantra Connect and latter scale up with Andon board for a birds-eye view of the shop floor. To know the downtime reasons, operator targets it is recommended to have a tablet. We can support one Tablet for multiple machines so that your costs are minimized

11. Is Air gauge and bar code scanner supported?

Yes, there are 2 USB ports in each Yantra connect device to support these devices

12. What are the specifications of Yantra Connect

Hardware:

There are 6 Inputs and 2 PWM outputs @24V DC. Also, Thermocouple, 4-20mA current loop, current transformer, RS232/485, Ethernet, Bluetooth can be connected.

Software:

MTConnect, OPC-UA, Modbus, OTA, etc., Secure Cloud/On-Premise hosting

This flagship product is the Yantra platform that is under continuous improvement. For specifics please reach out to us so that any of your requirements can be addressed.

13.How to decide between On-premise and Cloud solution?

We recommend our secure cloud solution based on the subscription model. This will eliminate the need for a Computer, backups, etc.,. However, if you prefer to have on your computer, our solution will work as well.

14. Does Yantra 24x7 connect with ERP software?

Yes, Interface to ERP is through APIs. Please reach out to us, so that we can propose the best solution

15. What happens when a network connection fails and then reconnects?

The data will be saved locally and uploaded automatically when the connection is restored.

16. Can setting time per machine be captured?

Yes, we can collect them automatically or we can enable tablets or other devices near machines for manual input.

17.If the connection is lost during program transfer what happens?

It is recommended to transfer the program again.

18. Does the system raise alerts for the end of tool life?

If the machine raises this alarm, we can relay the notification to you. Please reach out to us, so that we can propose the best solution

19. Does Yantra 24x7 store the history of operators in shifts and which machines they operated on?

Yes, the supervisor can allocate operators to shifts and machines and later analyze the historical data to determine which operator on what machine worked with the best or the least efficiency.

20. Is Dual spindle / Multiple axis machines supported?

Yes, dual spindle machines are supported. Multiple axis machines are supported as well.

21. Can Part Program Version, changes be tracked?

Yes, Yantra Vault is designed for this along with a host of other Part program management features. Please reach out to us to know more

22. Mobile app Can be locally hosted within the organization’s boundaries?

Yes, the Mobile app can be hosted locally and thus will not be accessible outside of the organization.

23. Can the system send alarm notifications to the supervisor when allowed Idle time is exceeded?

Yes, Supervisors can set alarm notification in the step of 5 min when max Idle time is exceeded